WELCOME TO KERIONICS

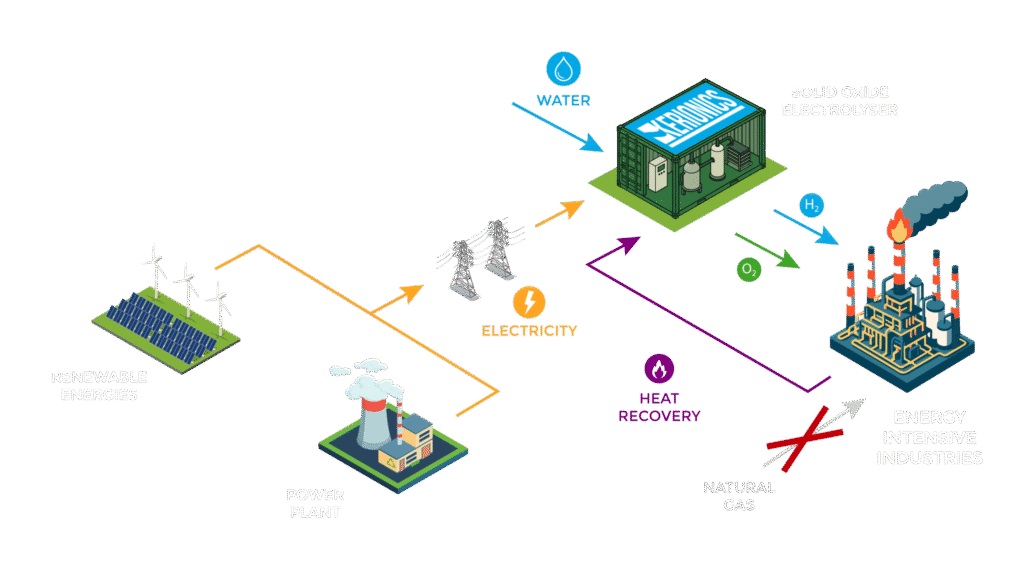

GAME CHANGER SOLUTION: Electrolyser producing H₂ for Hydrogen combustion

Electrolyser producing H2 for Energy Intensive Industries combustion

SOEL VS OTHERS

Solid Oxide High Temperature Electrolysers are 30% more efficient than Alkaline and PEM Electrolysers

Electricity need in SOEL

SOEL’s Electricity needs

- Generate steam

- Split Oxygen and Hydrogen from steam

Heat recovery

The energy released by the EII during combustion is mainly Heat. Heat could be recovered to generate steam in the SOEL Electrolyser.

Low electricity consumption

Heat recovery cancels the electricity need for steam generation

Oxygen in used

In a stand-alone SOEL, oxygen is a waste. To dilute the Oxygen, a lot of compressed air is normally provided. Hydrogen combustion will use Oxygen. No need for compressed air. Reduction in NOx.

Low OPEX Low CAPEX

- SOEL more efficient

- Heat recovery

- Oxygen not wasted

- SOEL Electrolyser is simpler

What is Kerionics?

At Kerionics we face the great challenges of industrial decarbonisation and energy transition with cutting-edge technology.

Since 2022, we have been developing high-temperature solid oxide electrolysers (SOEC), which can generate hydrogen and green oxygen more efficiently and competitively.

Our technology is key for energy-intensive industries seeking to reduce their carbon footprint without sacrificing productivity.

At Kerionics we are working to industrialise SOEC, optimising costs and improving our clients’ energy efficiency, thus driving a more sustainable, low-emission economy.

Innovation for industrial decarbonisation

Efficient and competitive production of green hydrogen